For a long time, AT gearbox has been regarded as the shoulder of the gearbox industry, which is loved and touted by the majority of riders. It is fuel-efficient, resistant to operATion and can be trampled at will. As long as AT is mentioned, people will involuntarily think of these labels. However, from the actual maintenance ratio, AT is not as reliable and durable as the legend, and with the increase of service mileage and years, the failure rate of AT gearboxes is increasing day by day. The most important thing is that due to the high precision of AT gearboxes, the maintenance prices of 8AT and 9AT gearboxes are also expensive. So if someone tells you that the AT gearbox can be operated at will, you should give him a big face-scraper!

Why on earth? Please look down!

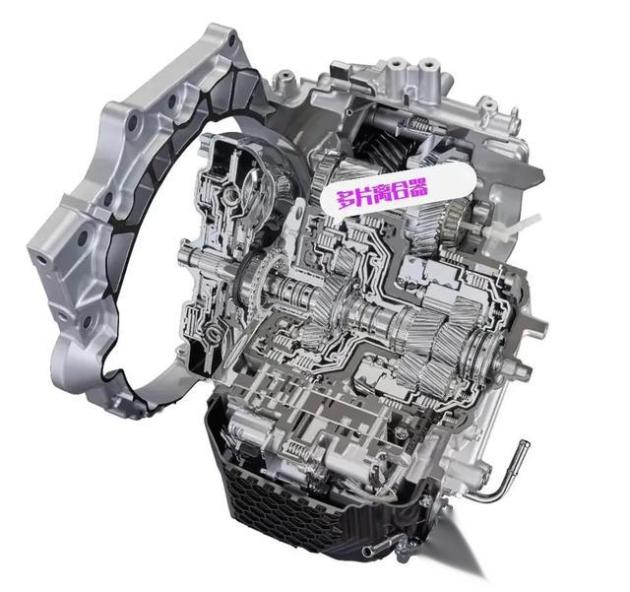

AT gearbox adopts planetary gear sets to change the transmission ratio, and the engine power is input to the input shaft through the hydraulic torque converter, and then the change is realized through the natural gear ratio of sun gear, and. Multiple clutches are designed in the gearbox to fix the planet carrier or ring gear of planetary gear sets to realize the output of different speed ratios. In addition, the combined speed ratio can be realized by fixing the planet carrier and ring gear of multiple planetary gear sets at the same time.

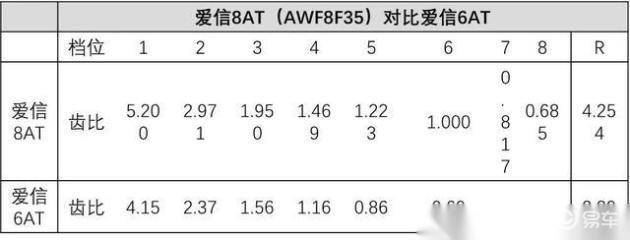

Usually, a set of planetary gears can achieve three different speed ratios, and six different speed ratios can be achieved through two sets of superposition. However, considering the actual speed output, not every speed ratio is usually effective.

AT gearbox and engine are usually buffered by hydraulic torque converter, and engine power is transmitted through. The hydraulic torque converter is actually a closed cavity filled with gearbox oil. The principle of power transmission is that the engine drives the pump wheel to rotate at a high speed, which drives the gearbox oil to flow at a high speed, and the gearbox oil drives the rotation, and finally drives the turbine to rotate synchronously. The output shaft of turbine is connected with the input shaft of AT to realize power transmission.

Because the transmission oil transmits power, the efficiency is relatively low. Therefore, in order to improve, it is considered that the hydraulic torque converter is internally designed with a lock-up clutch. After a stable start, when the speed reaches more than 10km/h, the lock-up clutch locks. Form. However, when starting, shifting and braking, the locking clutch inside the torque converter is separated, which can allow the speed difference to occur. Avoid engine stalling.

In order to protect the planetary gear set AT the back end of AT gearbox, the locking clutch of hydraulic torque converter is separated at the moment of gearbox upshift, and the multiple clutches in gearbox are quickly separated and combined at the moment of gearbox upshift, so as to realize different speed ratio output.

There are many parts of AT gearbox, usually reaching more than 400, especially for automatic gearboxes with multi-gears, such as 8AT, 9AT and 10AT. The size of parts is more compact and precise, especially for AT gearboxes with multi-gears, the shifting logic is very complicated and the valve body action is extremely complicated. There is a high requirement for the cleanliness of transmission oil. Therefore, AT gearbox needs to change gearbox oil regularly. Otherwise, the valve body may not open and close normally due to excessive impurities.

Many people think that AT is resistant to exercise, and can pedal with big feet and drive violently at will, which is quite wrong. The interior of AT gearbox is quite precise. When driving violently or even launching, although AT gearbox has a hydraulic torque converter for buffering, especially when shifting gears, the locking clutch can be released to form buffering, but the power transmitted by gearbox oil is also impactful. At the moment of shifting gears violently, the engine speed often rises rapidly, and the instantaneous impact force is relatively strong, which will certainly bring wear to multiple clutches used to lock planetary gear sets inside the gearbox. Therefore, the service life of the gearbox will be greatly reduced.

The key of automatic gearbox is to avoid shifting shock as much as possible.

- 1. When starting, don’t hurry to refuel. After shifting into D gear, wait until the power is turned on and the gearbox is full of energy, so as to avoid high-speed impact. Don’t play until the ejection starts.

- 2. Don’t drive violently with the big foot throttle when the car is cold, and the engine speed is too high, resulting in too much impact at the moment of shifting.

- 3. Try not to use the manual mode unless necessary, especially for the instantaneous downshift of the high gear. Although the shift can be protected instantly, the speed ratio of the gearbox changes too much in the manual mode and the impact is relatively strong.

- 4. Change the gearbox oil regularly, once every 60,000 yuan. It is recommended to change the gearbox oil by alternately combining the circulating machine and gravity, that is, after changing the oil in the circulating machine, replace the filter element at the same time at the next gravity oil change.

I am talking about cars, thank you for reading, and welcome to communicate in the comment area!