This paper makes an inventory of why some products in interest communities have changed from being popular to being tepid now, and further analyzes the opportunities of new products in interest communities.

Perhaps many people have forgotten why people went online 20 years ago.

"I want to watch the news" and "I want to chat" are the basic needs of the first batch of netizens in China.

In essence, this is the rightcontentandsocial contactDemand.

Community products that meet these two needs have always run through the Internet.

From various chat rooms, to xici, and Baidu Post Bar, which is popular for a while, many popular people and popular content have been produced in these communities. In the 20 years of the fastest development of the Internet in China, these communities have also nurtured different styles of Internet content culture.

Let’s turn the camera back to the present, 2019.

The waves behind the Yangtze River push the waves before, even if it is a king like Baidu Post Bar, it has been unstoppable in recent years.

With the development of technology, many new community products began to shine, such as short video community in Aauto Quicker, Tik Tok, question and answer community in Zhihu, sharing community in Little Red Book and so on.

While those who retain the dignity of interest-oriented communities are all vertical communities in a certain field, such as Tigers and car home.

Then the question is, why didn’t an interest community emerge like the post bar in those days?

What does the peak Baidu Post Bar look like?

In terms of activity, taking the two big brothers, World of Warcraft Bar and Li Yiba, for example, it is not a problem to refresh a page and a half in one second.

From the perspective of cultural output, there are countless online hot words born in Post Bar. Words such as "Diaosi" and "Gao Fushuai" from Li Yi Bar have long been broken and used all over the network;

From the big event, "Jia Junpeng, your mother asked you to go home for dinner" is not familiar? In 2008, it was World of Warcraft that set off the "anti-Korean jihad" on the whole network.

Not to mention that Crouching Tiger, Hidden Dragon’s Post Bar has high-quality content exporters in various fields. For example, the well-known digital evaluation up master "Pen Bar Evaluation Room" in bilibili now comes from notebook Post Bar.

There are many highly active post bars under various categories such as games, novels, campus and animation. In 2016, the DAU of the post bar reached 3000W W.

However, if we can clearly point out the peak period of a product, it means that the product has fallen from the peak.

I talked to my friends at Baidu Post Bar.In 2018, the DAU of Post Bar has fallen below 1000W. After the activities in 2019 and the Spring Festival Evening, the DAU of Post Bar has probably risen to 1350W W. Up to now, I have not obtained the specific DAU value of Post Bar, but it should be around 1000 W or even lower.

It is true that the products with daily activities are very large, but they are not as good as their past.

Moreover, as far as I know, the staff of Post Bar has also greatly declined this year.

Internet products are like sailing against the current. If you don’t advance, you will retreat.

Baidu post bar, slowly walk down the altar.

Compared with other fields, there are not so many people in the field of interest community.

In 2014, after a period of uproar, the interest tribes who independently launched the APP from QQ had no sound in the past two years. We can see that the interest tribes are not living well through the download volume estimation.

(Interest tribe IOS downloads estimated data-from seven wheat data)

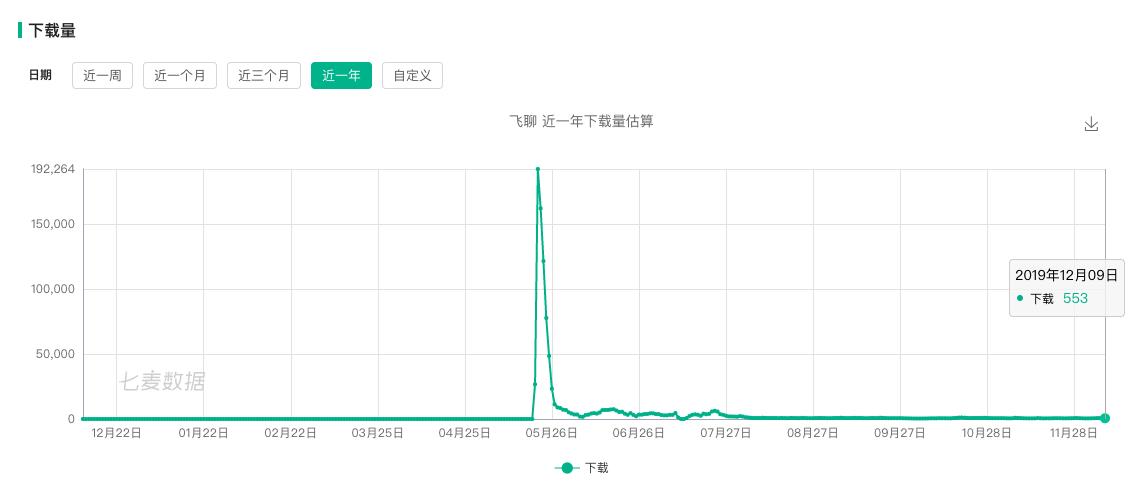

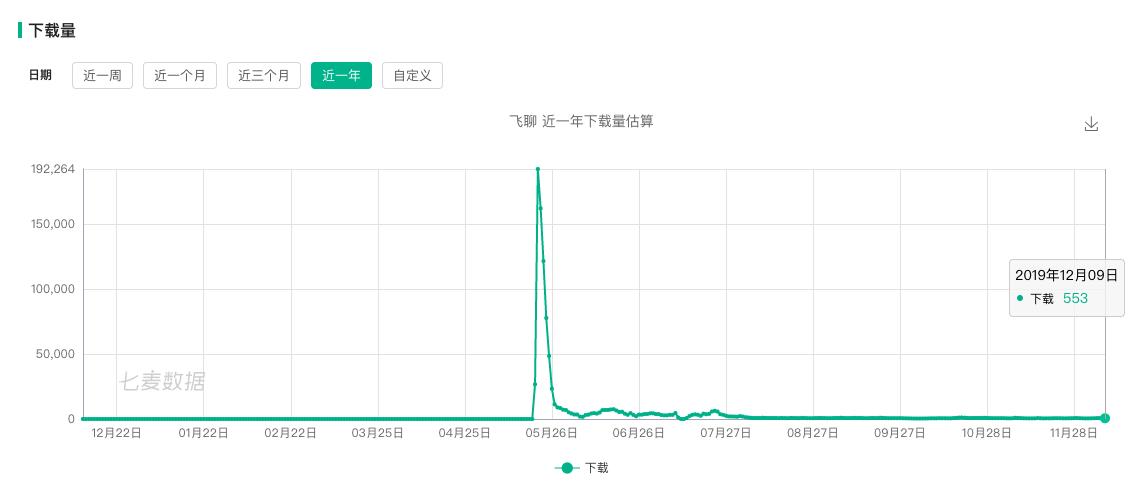

In the first half of this year, the headline products flew online, shouldering the heavy responsibility of impacting Tencent’s social moat, but it was only a flash in the pan.

(Fei Chat OS downloads estimated data-from seven wheat data)

After all, even compared with the current Baidu Post Bar APP, their data is several orders of magnitude worse.

(Baidu Post Bar IOS downloads estimated data-from seven wheat data)

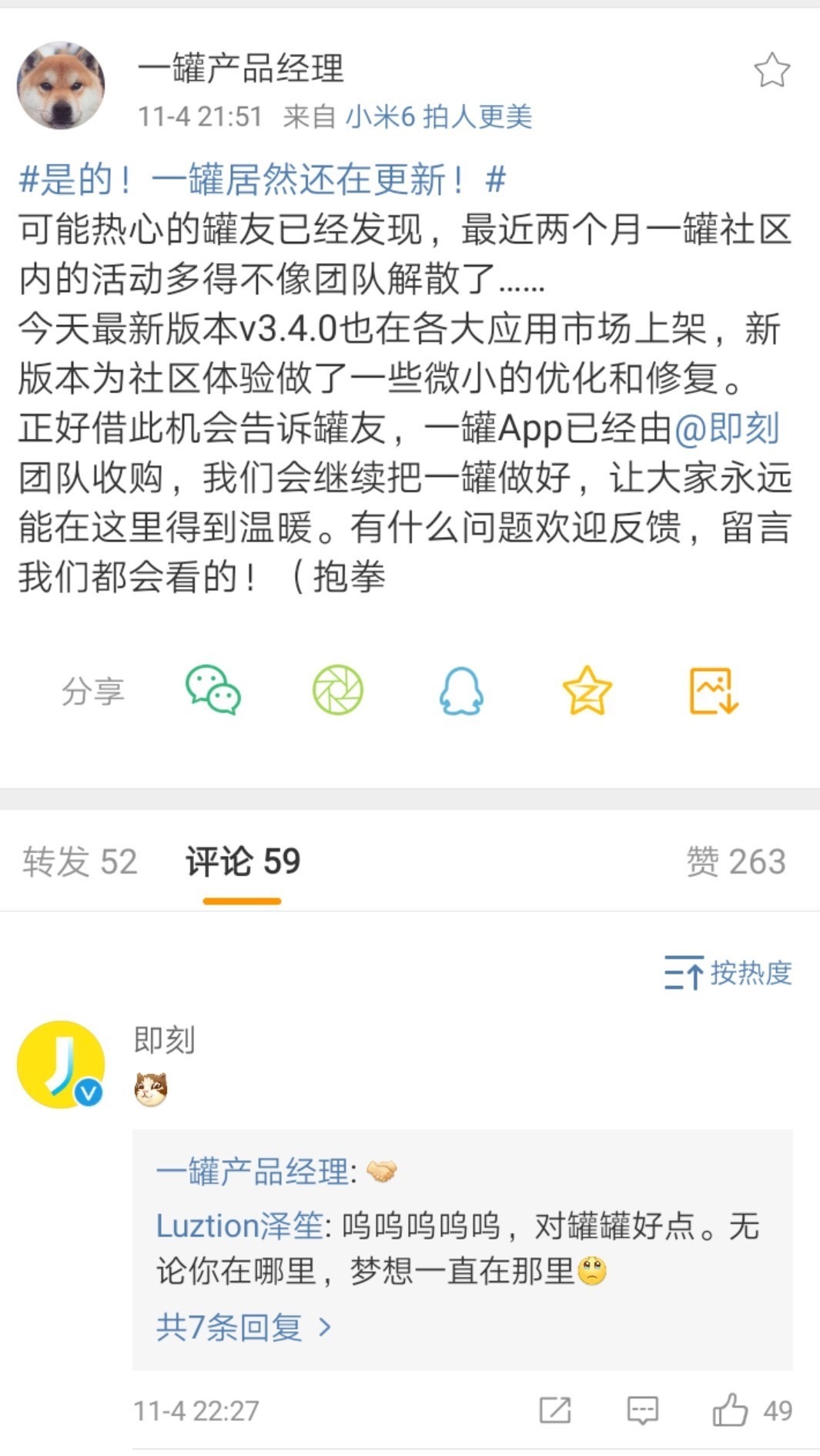

In addition, it is also in the direction of transforming into an interest community immediately. If it is not removed, it should take shape.

At the same time, I have to mention the contemporary products of Baidu Post Bar:halves of a bean.

Douban group is actually well received at the user end, and there are also big head groups like Douban Goose Group, but the official attitude of Douban to the group is a bit vague.The whole company didn’t take the team as the focus.

Judging from the fact that users of "Aidou Group" and "Anti-Abei Dictatorship Group" actively put forward suggestions to report bugs, it seems that users have deeper feelings for the group than the official.

(Douban Group-Aidou Group)

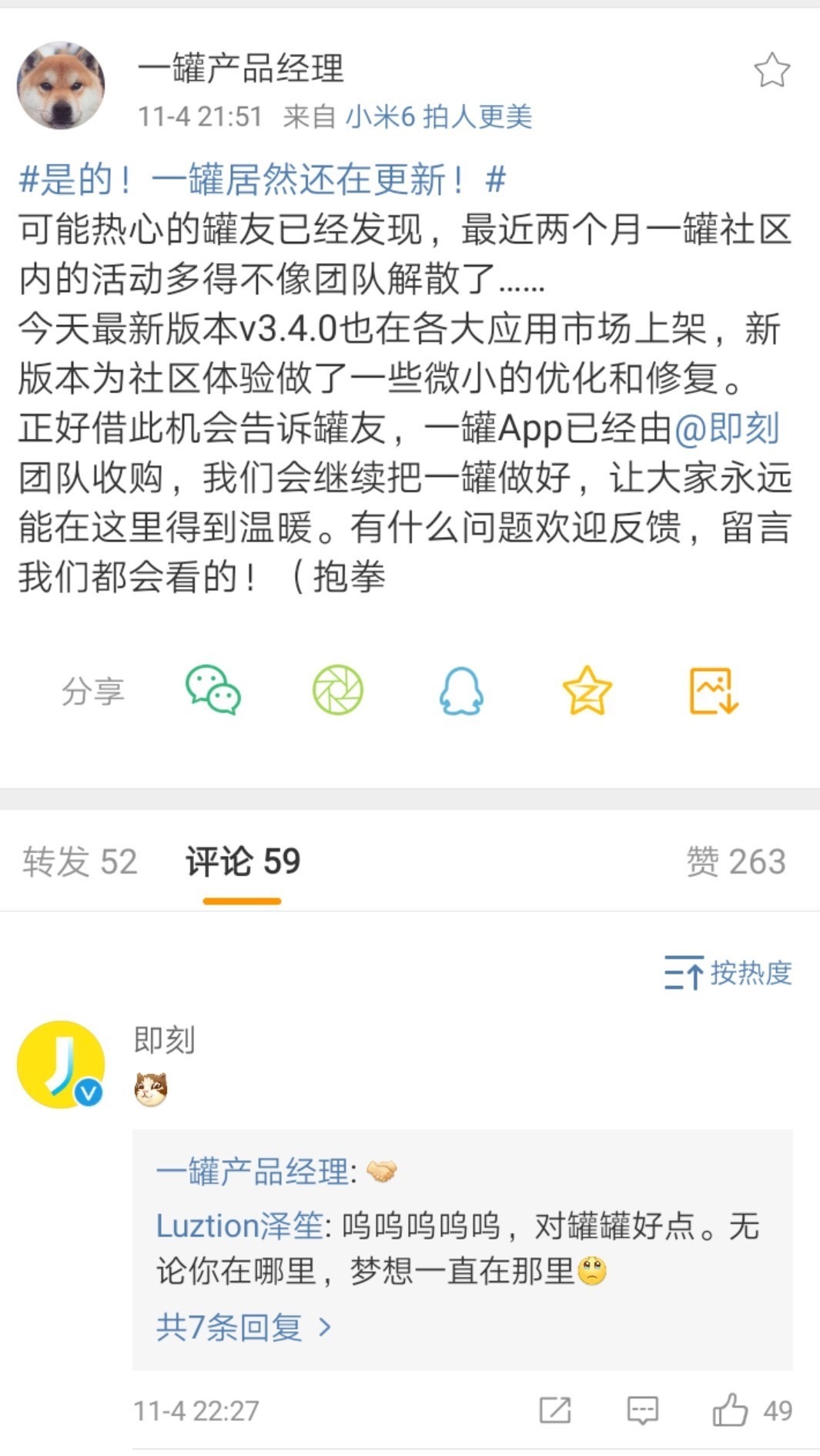

There are also some niche products mixed with social and interest communities, such as soda and a can (just acquired immediately), which are generally tepid.

Why are these new interest communities not working?

Many times, when we look at the content of a formed community, we will find that the content of this community seems to have no focus, as if a group of users are sharing their daily lives or discussing some hot news.

For example, the pedestrian street, the largest section of Hupu, mostly contains a group of straight men talking about life, work and hot news, and there are also basketball-related contents, but not many.

Some people think that this is the main content in the community, so as long as you find a group of users who love to chat and share, and put them together, you can naturally chat.

So I spent a lot of money, and I bought DAU to tens of millions a day, and the purchase was cool for a while, and I kept it in the crematorium.

This is completely putting the cart before the horse.

Like Hupu, most users began to share their lives and express their opinions on hot news, which should actually be regarded as one of the signs of community success.

This means that this situation is the result of community success, not the reason for community success.

Anyone who has really mixed up with the community knows that most users are attracted by the characteristic content of this community first, then slowly like the atmosphere of this community, and finally fully recognize this community and its users.

When the user recognizes this community, he will be willing to share his anxiety, doubt and pain in this community in a unique way.

For example, in V2EX, a programmer community, there are not only technical discussions, but also many people who care about hair loss, sudden death and career development.

For example, in tiger pounce, when JRs are green, they will come to the pedestrian street to post.

(Tigers often share their experiences of being green.)

But recognition is a process, and no user can recognize a community as soon as he reads a few posts.

If a community does not have distinctive content and a good user atmosphere, why should users recognize this community?

From this perspective, look at these new interest communities again, and you will find that these apps are good in terms of first feeling, vision and interaction.

However, a closer look shows that there are very few communities that can achieve distinctive content, let alone the user atmosphere.

We might as well study what successful communities did right when they accumulated traffic in the early stage.

In my opinion, the core of community success is two things:

- First, output accurate and high-quality content.

- Second, establish a good sense of participation mechanism to let users chat.

Both of them have a bilateral network effect. If China Unicom can be penetrated, a community will form a very good growth model.

Simply put, it is the reason for users to come to the community and the motivation left for users. If users stay, they will continue to give new users reasons to come to the community.

We often say that the traffic grasper is nothing more than these three:Tools, benefits, content.

In addition to Baidu Post Bar, a community product backed by search traffic dad, other interest community products rely on content to obtain seed users in the early stage.

These contents have two characteristics:The field is vertical and the quality is quite high.

At the beginning, the tiger pounce won the first wave of high-quality basketball fans by relying on the founder Cheng Hang to manually carry first-hand NBA information in Chicago.

At the beginning of the new oxygen, it also relied on the official team to take field photos of major plastic surgery hospitals and carry high-quality plastic surgery related materials from abroad, which gained the first wave of attention.

We expand the scope from "interest community" to "community", and you will find that this still holds:

At the beginning, the little red book in the sharing community was a PDF file called "Outbound Shopping Guide";

Zhihu, a question-and-answer community, became famous at first through high-quality answers.

Users who come through content will also have higher accuracy and quality, which is more in line with the characteristics of core users in the early stage.

In most communities, the sense of participation mechanism is equivalent to the UGC mechanism. If we use more understandable words, this is called:

Atmosphere!

Shaping the atmosphere does not require strong product functions, and establishing UGC mechanism does not mean that online level and incentive system are needed.

Most importantly, you need to let users know what they should talk about and how to talk.

For interest communities, the question of "what to talk about" is not difficult, and interest itself is the most important theme.

The difficulty is "how to talk".

Some community operators are content-conscious and know how to distribute some dry goods in the community.

However, in most cases, when the content is sent out and users see it, at most, they just like it and reply to some meaningless words such as "thank you" and "awesome".

We can’t talk at all.

Be reasonable. It is better to be a WeChat official account for this unilaterally transmitted content.

And when we look back at how successful communities talk, you will find some very interesting things.

- First, the replies to most posts are not meaningless, whether they are clever or spiteful, but serious discussions and exchanges.

- Second, in most posts, the interaction between users in the comment area is very good, such as posting and tiger flapping, and two people can brush several versions of messages.

- Third, there will be many popular posts, not because of the content of the poster, but because of the content of the comments replied by God, and the rightmost one has done this to the extreme.

After a while, the atmosphere of chatting came out, and the sign of the formation of community atmosphere was the formation of some community slang.

As far away as "Li Jufu" and "Laixin Chop" in the post period, as close as "I’m ready", these are not only a community slang, but also a community culture.

Atmosphere is the moat of a community.

In fact, the atmosphere of community products will set the tone in the early stage of products. For example, Zhihu’s rigorous and serious attitude was slowly cultivated during the period of invitation system.

These foundations all depend on the initial group of core seed users, who must be professional and enthusiastic.

Moreover, even with this group of users, the community atmosphere will not be achieved overnight, and it will take time to slowly precipitate.

The community has to cook soup slowly, and impatience can’t be done well.

I have to say that compared with the brilliant years of Baidu Post Bar, the current market environment has been very different, and it is these differences that make it more difficult for excellent communities to appear.

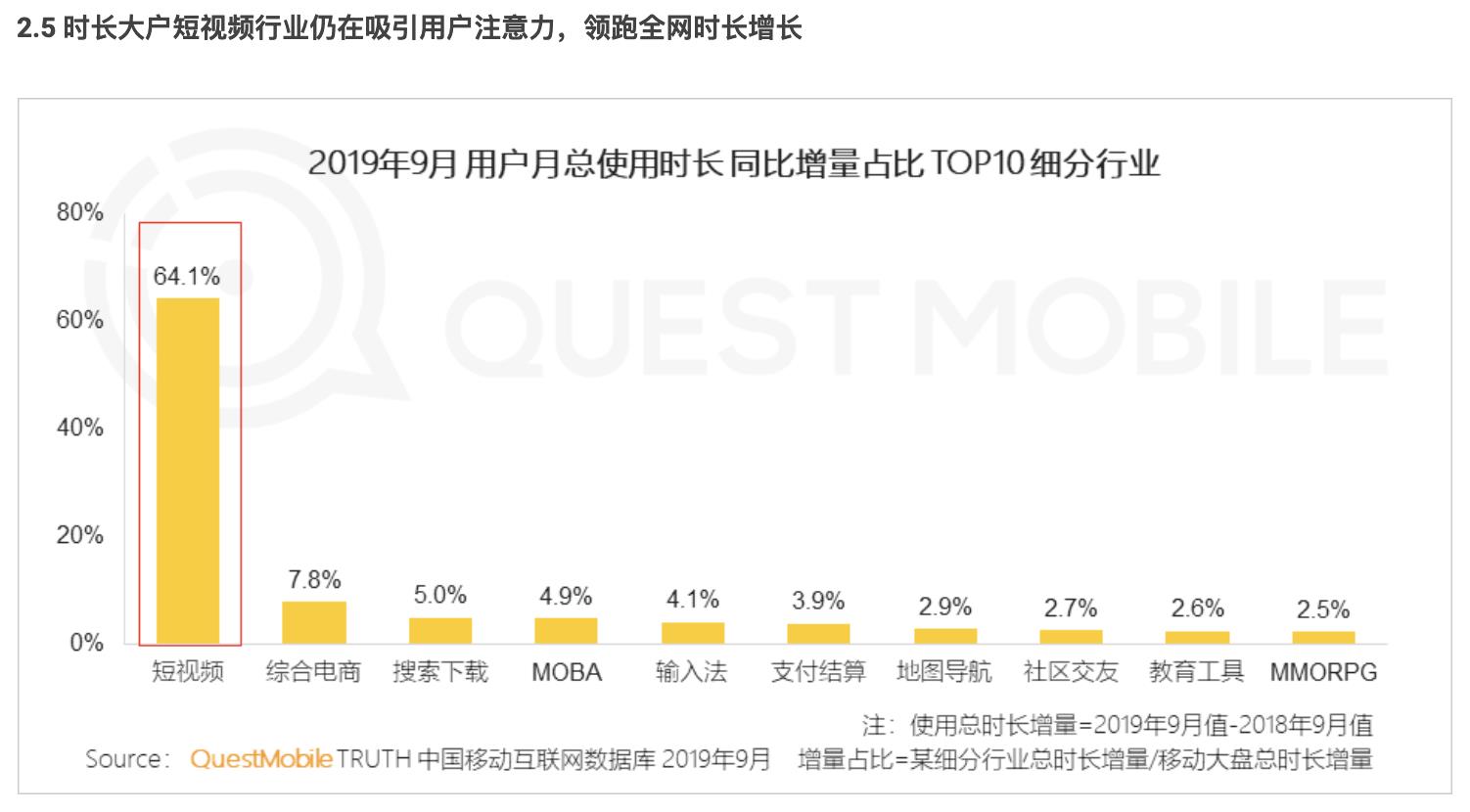

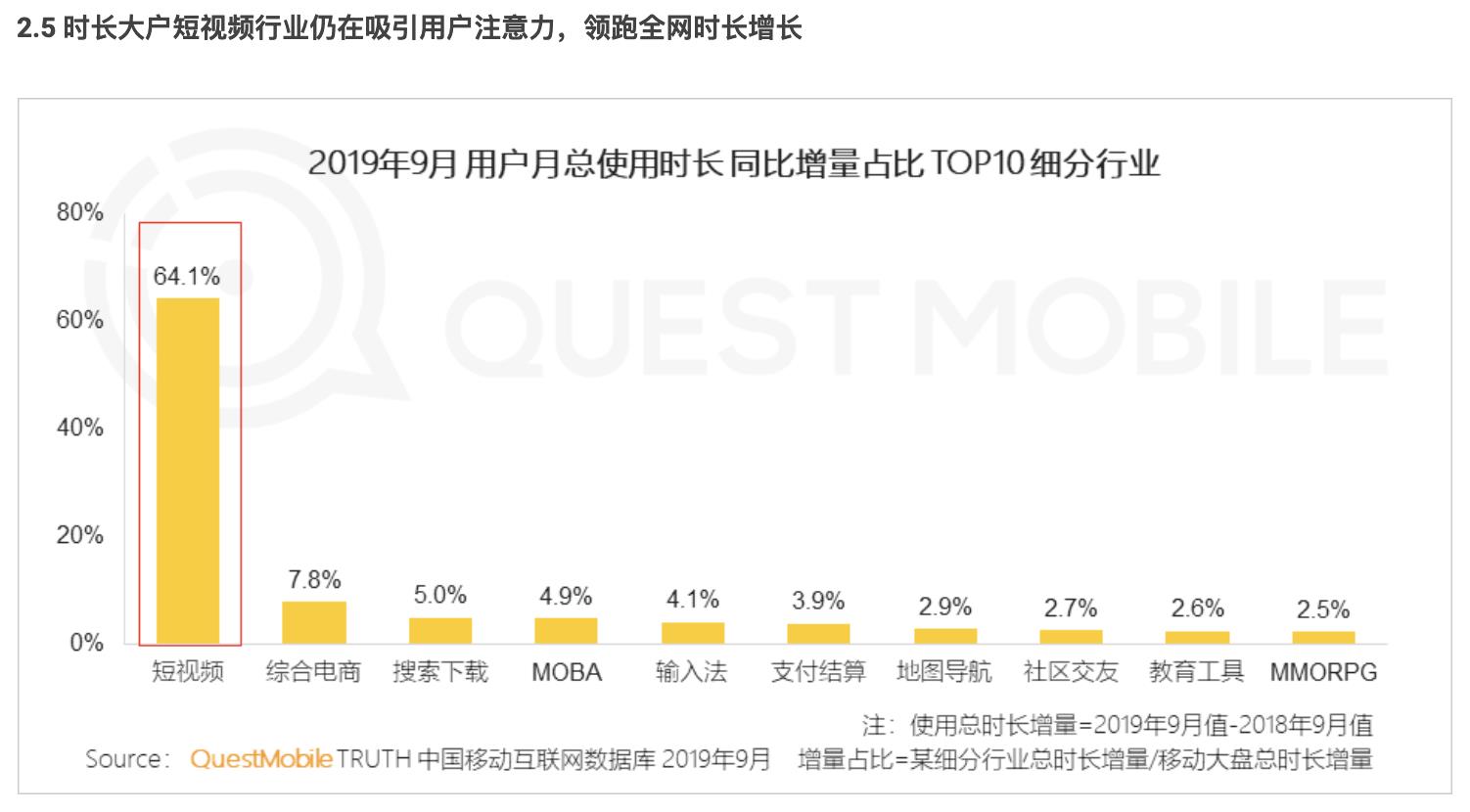

In a community, 90% of users are content-consuming users who only watch and don’t speak. For such users, the content experience of short videos is better, so most users will replace community products with short video products.

Because short videos have a strong ability to grab users’ attention, Aauto Quicker and Tik Tok will even become the second competing products of live broadcast platforms such as Betta and Huya.

(From QuestMobile: cmnet Autumn Report in 2019)

During Tianya Forum and Baidu Post Bar, most content producers used love to generate electricity. At that time, it was not easy to accumulate fans, nor was it easy to realize fans, and it was even more difficult to realize simple content.

Now, there are a lot of ways to realize the realization of people who have the ability to produce content. Everyone is profit-seeking, and they all do positive feedback timely and strongly, which invisibly reduces the number of high-quality content producers in the community.

Since the second half of 2017, the position of "growth hacker" has continued to become popular, and cases such as "3 days and 0 costs increased by 100W users" have emerged one after another.

The threshold of bosses and investors is constantly being raised. If a new product can’t do tens of millions of daily jobs in a few months, it is a slam.

But this kind of thing, interest community, itself is slow work and fine work to do well.

However, this does not mean that the track of the community of interest has no future.

People are gregarious animals, and finding a group and a sense of belonging are the needs written in genes.

In addition, Tencent, Zhihu, Toutiao, Nail and other big companies have entered the market one after another, and all of them have launched their own interest community products, which also means the huge opportunities hidden in the interest community.

Opportunities are accompanied by challenges, depending on who can take the lead in finding a reasonable growth model.

However, countless past experiences also tell us that the first person to find a growth model may not have the last laugh.

However, it is these unknown futures that make people excited and excited.

Although the current interest community products are basically "circle" and "group" models, there are also some products with differences that make me shine.

A successful Q&A community does have natural advantages if it wants to breed a successful interest community.

Aside from the advantages of traffic, Zhihu itself has a mature community atmosphere and a lot of professional content. So, what is important for interested communities is already available in Zhihu.

It depends on the performance afterwards.

Backed by the traffic of WeChat, as long as WeChat wants to push, the quantity is definitely not worrying.

The worry is how to keep it, and how to solve the problems of content and atmosphere. If Haowuquan starts to cooperate with WeChat WeChat official account in depth, the chances are considerable.

I’ve been thinking for a long time whether to put it up immediately. After all, it’s getting cold immediately, and I’m not sure whether I can come back.

Thanks to the function of content subscribers, a large number of instant users are Internet practitioners, so a community called "product manager’s daily life" quickly formed after the later transfer to the community.

As mentioned above, if users recognize a community, they will be willing to share some anxious, confused and painful things in this community.

And the immediate "product manager’s daily routine" was done.

Now I immediately received a can, and I don’t know how the follow-up will develop, which is worth looking forward to.

Generally speaking, interest community products will use content as a traffic grasper to acquire users, but Utopia, a product, takes a different approach and chooses tool attributes.

It has a set of very powerful background management functions. As an operator, you can create your own community and customize many functions, from user incentive system to content partition, the functions needed to operate the community are clear.

This also means that the Utopia product was initially aimed at B-end users, that is, operators in various communities.

This is indeed a different idea from other communities. With the development of WeChat WeChat official account, headline number and live broadcast platform, KOL is more and more subdivided and vertical, and there are not few KOLs with high commercial value, such as Li Jiaqi and papi sauce.

There is no guarantee that KOL in any field needs such a product to run a community. After all, the user operation functions of WeChat and Weibo are too weak.

However, as mentioned above, the core of the community is characteristic content and user atmosphere. It remains to be verified whether it can help operators solve the problems of content and atmosphere from the perspective of tool attributes.

Yes, I also put bilibili in here, and this is my favorite.

From the point of view of interest community, where are you most likely to find some content of very small interest at present, and where can you find people who like it? I think it’s just bilibili.

Unlike video websites such as iQiyi and Youku, bilibili has a highly recognizable user atmosphere and a wide range of content.

Although bilibili still looks like a video website at present, who knows the future?

As a community enthusiast, I sincerely hope to see more good community products.

Everyone is afraid of loneliness, everyone needs to find their own group, and everyone needs a sense of belonging.

In the vast expanse of the country, you can find people like yourself, which is the meaning of the Internet.

This article was originally published by @ Ye Xiaozhao. Everyone is a product manager. It is forbidden to reprint without permission.

The title map comes from Unsplash and is based on CC0 protocol.